When did wool recycling start?

Discover when, where and how wool recycling started and evolved over time

In the last few years, thanks to the rise of awareness on sustainability and the diffusion of the circular economy, recycled wool has become of prime importance in the textile and fashion industry.

That’s because it is one of the few fibers that enables a low-impact, mechanical, closed-loop or ‘textile-to-textile’ recycling process to produce high-quality products (Read more on 5 reasons why wool is the circular fiber par excellence). It might sound like an innovative thing, but it actually dates back to a long time ago. So let’s jump back in time to see when, where and how wool recycling started and evolved: an evergreen and circular practice that gives new life to old garments and scraps.

It was 1813, in England, when some Benjamin Law invented the first wool recycling machine and paved the way for what nowadays is seen as a great example of circular economy.

It all happened in the Leeds area, which had been a major center of woolen cloth production for centuries. The English cloth trade suffered a lot during the Napoleonic War, as the country did not produce enough wool and the war restricted the amounts of importable wool (because of the embargoes), even though the demand of woolen cloth was increasing. It is in this context that recycled wool was born, when necessity is the mother of invention.

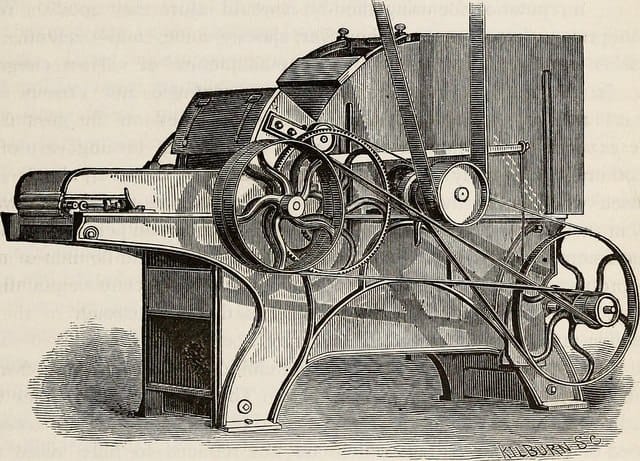

In a town called Batley, some Benjamin Law had the intuition of using old garments as raw materials and developed the first, dry-working, recycling machine (also called “Devil”) which, through metal nails on rollers rotating at different speeds, recycled wool garments into new fibers.

This process had a a revolutionary effect on the textile industry, it shaped the wool recycling value chain that is still here today.

New professional figures appeared in the textile value chain and Batley (together with some nearby towns) became the major center for the rag collecting and sorting business, as well as the the biggest producer of recycled wool. Wool scraps were collected not only in England, but in European countries, such as Germany, Austria, America and Australia.

Just as today, rags were manually sorted, cleaned and divided by quality and color: woolens and worsteds would go to wool recycling, while cotton rags were used to make paper.

Also leftovers always found a use. Any seams, unsuitable rag, or recycled fiber that was too short to be spinned, were gathered and then sold to farmers to manure crops, or they were used for bedding and stuffing. The selected rags were then recycled with Benjamin Law’s machine.

There were two kinds of recycled wool, depending on the input rags and the resulting fiber. Let’s see their differences:

Nr. 1

"SHODDY"

“Shoddy” was the better quality of recycled wool fibers (usually longer than 20mm and soft) and was obtained by recycling worsted wool knitwear. The name’s origin is uncertain, some say that it comes from the English “Should Go”.

Nr. 2

"MUNGO"

“Mungo” was a lower quality of recycled wool fibers (usually from 5 to 20mm) and was obtained by recycling tailors’ offcuts, and milled, compact fabrics. Even here the name’s origin is uncertain, some say that it comes from the English “Must Go”.

No matter if it was “Shoddy” or “Mungo”...

…These fibers were then mixed with new wool (virgin wool), spun through the woolen process (Read more on what is the difference between Worsted and Woolen Textiles) and woven into new fabrics. Already at that time, the wool recycling industry was producing many types of woolen fabrics, such as Meltons, tweeds, flannels and doubles; which were often used for military uniforms.

Some years after Benjamin Law’s innovation, rags arrived in Italy too. They were traded in Naples and Palermo, thanks to their ports, and were mostly shipped to Prato – in Tuscany – which was the town where regenerated wool had its greatest impact, so much so that it soon became the ‘rag town’ of italy.

In 1850, a Neapolitan, resident in Prato, Count Temistocle Biaggio, established the first dry-regenerating plant in San Martino di Prato. However, the actual turning point came four years later, in 1854, when Francesco Pisani and Carlo Valdré took inspiration from the paper industry and improved the machine, transforming it into a “wet-recycling machine”, which recycled rags through the same metal nails on rollers rotating at different speeds, but in tanks with running water – a technique that was originally used to produce paper pulp from the recycling of cotton rags.

This process was a real success, as it produced clean and longer fibers, which were similar to virgin wool. But that’s not it, in 1870, the Carbonising treatment arrived in Prato. Through this process, rags were treated with sulphuric or hydrochloric acid removed any vegetal fibers from them, ensuring a greater cleanliness and the total elimination of impurities. From this point on, regenerated wool started to improve and became highly efficient. There were many wool merchants in Prato, and they could provide all grades and colors of regenerated wool. This trading became more and more important for this town, so much so that “Prato wool” was often used as a synonym for recycled/regenerated wool.

The circular economy was not in people’s mindset back then, but they unconsciously pioneered a technique that is now fundamental for a more responsible and low-impact fashion.

In fact, the economic aspect was a major factor in the success of regenerated wool among. Usually, raw materials made up 40% of the textile manufacturing costs, but regenerated wool made up only 25%. Moreover, the new recycled wool fabrics that were produced were already colored, thanks to the sorting process, which divided the rags into all possible shades, and so dyeing costs could be avoided, as it was not necessary (Read more on the art of creating colors with no dyes). All of this revolutionised and boosted the great success of the Italian woollen textile industry, which is still leading the market today.

As far as recycled wool is concerned, many things have changed over time. However, this process is still alive and kicking, it has overcome the initial quality prejudices and it is now becoming more and more important for many industries, not only fashion.

When recycled wool fabrics were born, they were cheaper and of much lower quality compared to virgin wool fabrics: a prejudice that has affected recycled wool for more than a century. However, the quality of today’s recycled wool fabrics is quite different, and it often equals virgin wool fabrics. All this with a great advantage in terms of reduced environmental impacts (Read more on what’s behind a recycled wool fabric).

Our company was born in 1941 with recycled wool, for the same reasons why Benjamin Law invented the dry-recycling machine: lack of virgin raw materials.

Along the years, we have taken this material to the next level and have also created our own brand MWool®, the next generation of recycled wool, which is used to create high-end fabrics and jerseys for the fashion world.

MWool® is a low-impact and high-end recycled wool that distinguishes itself for an accurate selection and deep testing of the best possible raw materials, a cutting-edge and low-impact mechanical recycling process of pre-consumer scraps and post-consumer garments , a masterful blending and color creation through our Recype® process, a painstaking quality control, our Durability Treatment. MWool® is the first-ever recycled wool with a Life Cycle Assessment approved by scientific community and certified EPD® Environmental Product Declaration.

About Manteco, Italian premium textiles and circularity since 1943

After decades in the fashion world, in 2018, we have created the Manteco Academy project, through which we give webinars, in-person lessons and workshops on eco-design, circular economy and sustainability to numerous fashion schools, technical universities and brands worldwide. Thanks to this educative commitment and our heritage, we are often invited as guest speaker at events, panels, podcasts and conferences about sustainable fashion and circular economy.