5 Reasons why wool is the circular fiber par excellence

Discover why wool has all the prerequisites to be a key fiber for the future of a more responsible and circular fashion

Thanks to its value and circularity, wool allows a zero-waste processing from upstream to downstream, the production of durable goods and a low-impact circular economy, both for pre-consumer and, most importantly, for post-consumer goods

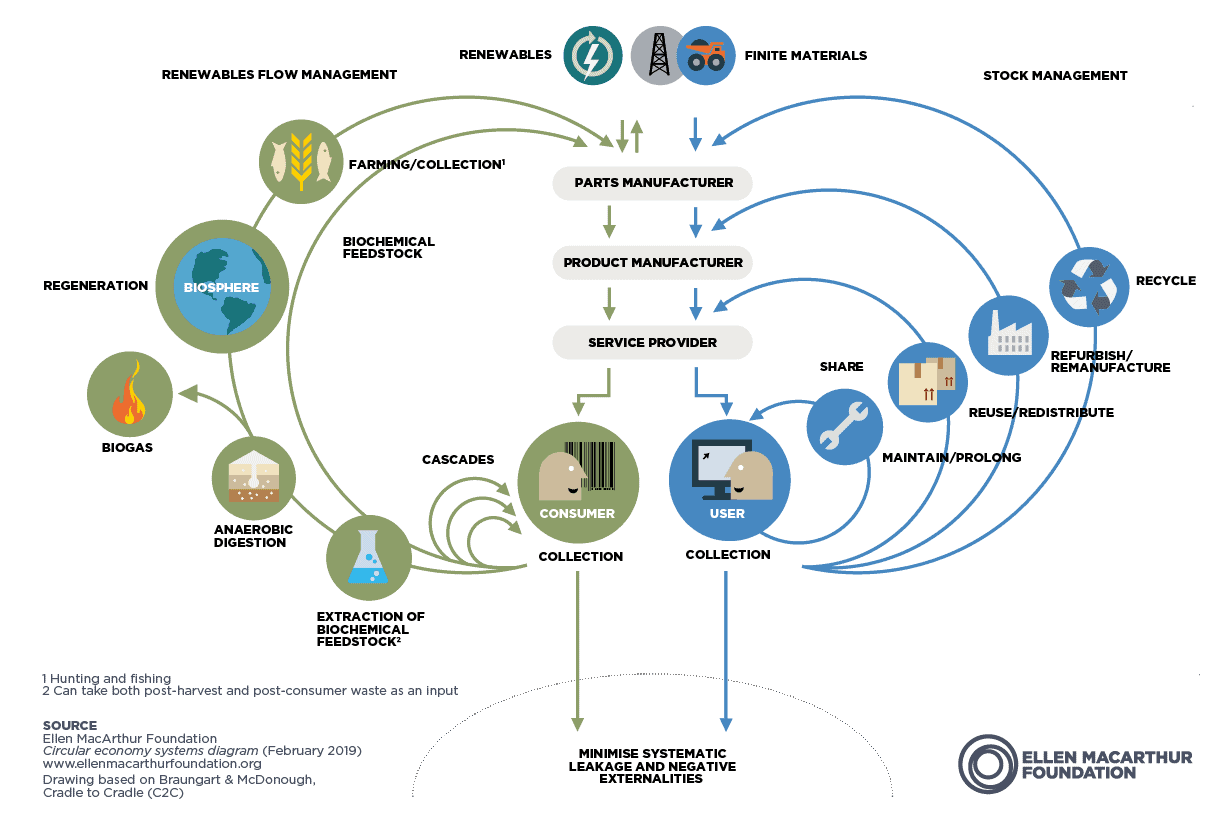

The entire world is running on two different business models. On the one hand, we find the old “linear economy”, where we take raw materials, process them to make products and eventually throw them away as waste. On the other hand, we find the growing “circular economy”, where waste should not be produced in the first place. According to the European Parliament, “The circular economy is a model of production and consumption, which involves sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products if possible. In this way, the life cycle of products is extended, thereby creating further value, and reducing waste to a minimum”. Circular economy should be an across-the-board practice, applied to all industries, as it can represent an instrument to drastically tackle the crisis, we are facing climate change, biodiversity loss, waste, and pollution. All this by keeping many resources in the loop for a longer time.

Adopting and increasing the circular economy in fashion could restore a balance that the industry’s lost control of and worsened over the last decades.

To support this claim, in a report made by the Monash Sustainable Development Institute, « Transitioning to a Circular Textile Economy in Australia », it has been seen that “100 billion garments are produced globally each year, with 33% going to landfill within the first year of purchase, and just 1% of total collected disposed garments are recycled. Most of the remainder is burned in landfills or downcycled into less valuable materials”. If the fashion industry increased this way of making business, it would significantly reduce all kind of stress to our planet: natural resources, animals, and plants, by also minimizing waste and pollution. As the Ellen MacArthur Foundation has it, “the circular economy is based on three principles, all driven by design: Eliminate waste and pollution, Circulate products and materials (at their highest value), Regenerate nature”.

Let’s see all the reasons why wool tackles and overcome all the circular economy's challenges.

1) NO FIBER IS WASTED - Either it is long or short, every virgin wool fiber is used to create valuable goods

After the “shearing”, the activity of cutting the wool off a sheep, fibers are classified by overall quality (fineness and lenght), yet nothing is left aside. On the one hand, long and uniform wool fibers go through the worsting process, which produce extra-fine yarns. On the other hand, shorter wool fibers go through the woollen processing. Both processes start with a process called “Scouring”, where wool is washed in hot water and detergent to remove general contaminants, such as dirt, salts from suint and non-wool protein material (during this process “lanolin” is collected, a natural byproduct used in cosmetics – a waxy substance that sheep naturally produce to protect their wool). Then fibers are dried and undergo a process called “carding”, which opens up fibers before the “combing” phase. During the latter, shorter fibers fall down (approximately 10%), but they’re not considered as waste, on the contrary. These fibers are called “noils” or “blousses” and are – by definition – “short fiber removed during the combing of a textile fiber”, which are gathered and used for carded spinning process to create high-quality virgin wool yarns and textiles.

2) NO PRODUCTION SCRAP IS WASTED - From the production of yarns to the final fabric, all scraps are recovered and reused as precious raw materials

During the production of wool yarns, fabrics and jerseys, all the scraps coming from different production phases are recovered and reused as raw materials, sometimes even without further processing (thus avoiding the use of energy), like spinning scraps, as the yarn has not been twisted yet. Leftovers that are coming from the coning and weaving phase (selvedges) are recycled into fibers and used again.

3) WOOLEN GOODS ARE LONGLIVED - Woolen garments and accessories last a lifetime, which is fundamental to avoid overproduction and keep materials in use.

The number of times a garment is worn significantly influences the overall environmental impact of that garment. Woolen garments and accessories are extremely durable and tend to last and stay in circulation for a long period of time. As the IWTO – International Wool Textile Organization – has it “Research shows that woollen products have the potential for several ‘lifetimes’, lasting 20-30 years and often longer”, also because its performance attributes, such as odour, stain and wrinkle resistance also ensure that wool garments can be laundered less often and retain their ‘as-new’ appearance for longer (Read more on how to take better care of wool garments)

Moreover, wool is highly valued in the resaleand, according to a Nielsen wardrobe study in collaboration with Woolmark, “50% of wool and wool blend garments are donated to charity, family, friends or sold”.

4) WOOL RECYCLING IS LOW-IMPACT - Woolen garments, accessories and pre-consumer scraps are easily recyclable through a mechanical, low impact process

In an ideal circular economy system, recycling should be the last resort, as we should be able to keep goods circulate and never lose their value. However, after a long use, also woolen goods are eventually wasted, and this is where the amazing circularity of wool comes into play. It is important to say that some fibers can be easily recycled through low impact mechanical processes, also making them a little cheaper than virgin ones, and encouraging their circular economy. On the other hand, some fibers can only be recycled through expensive and energy-consuming chemical processes, also making them more expensive than virgin ones, thus discouraging their circular economy. Animal fibers like wool are recyclable through low impact mechanical processes, while synthetics (like polyester and polyamide) require chemical processes and a lot of energy to be recycled. In fact, pre/post consumer wool garments and scraps are turned back into ‘new’ wool fibers through the so-called “shredding”, a process that involves a machine with two big cylinders covered with nails, which literally tear apart the garments and extract fibers. Wool garments are simply put on a conveyor belt and then comes out of the machine as ‘new’ fibers. All of this takes place without chemicals and with just a little water, which helps in opening up fabrics and knits structures and weaves.

This process gives life to shorter fibers, but they’re still high-quality and usable for luxurious recycled wool yarns, fabrics and jerseys, while saving 99,2% of CO2 emissions, 99,9% of water use and 93,3% of total energy consumption, compared to generic virgin wool fibers.

5) RECYCLED WOOL COLORS ARE CREATED WITHOUT ADDED DYES - By making the most of the colors that input materials had in their previous lives

Another important aspect of wool as a circular materials is that in the production of recycled wool yarns and fabrics, no additional dye is needed to create a color. You literally take advantage of the colors that garments and scraps used to have in their previous life. All this is possible thanks to the first – and fundamental – phase of wool recycling: the “sorting”. Here, pre- and post-consumer woolen goods are divided by colors and mechanically shredded – accordingly – to produce ‘new’ and colorful recycled wool fibers. Considering that millions of knits, garments and scraps are recycled every year, recycled wool warehouses are like a huge color archives, filled with hundreds of bales, each one with recycled wool fibers of different colors and tones. But this is just the starting point of the color creation. It’s basically the same that happens when a painter mixes different colors to create a new one. Different shades of recycled wool fibers are weighed in specific percentages and then carded (parallelized) to blend them and create a homogeneous color. This is what we call a “color recipe” or Recype®. This recipe is archived and adapted according to the kg of yarns that need to be produced. This way of creating colors has almost no limits, as by mixing different shades of fibers every tone can be achieved, except for fluo colors, and all of this is achieved without added dyes and chemicals, while preserving resources and cutting emissions, as every year – on average – we save 19.000 kgs of dyestuff, 11.000 kgs of chemical auxiliaries, 722.127 kgs of CO2-eq. Emissions, 10.641.878 MJ of energy, 122.707.000 liters of water. All resources that would have been used if colors were made with chemical dyeing.

In conclusion, it is important to note that when working with wool, you create durable goods, almost nothing goes to waste and almost everything (if well-designed) can be recycled - so much so that this precious fiber can easily live other life cycles.