The low-impact virgin wool by Manteco®

ReviWool® is the key ingredient of our high-end and zero-waste virgin wool textiles

This extra-fine and recyclable virgin wool is the result of our zero-waste philosophy and our will to eliminate value leakage in the supply chain by enhancing production cycle’s and material’s efficiency.

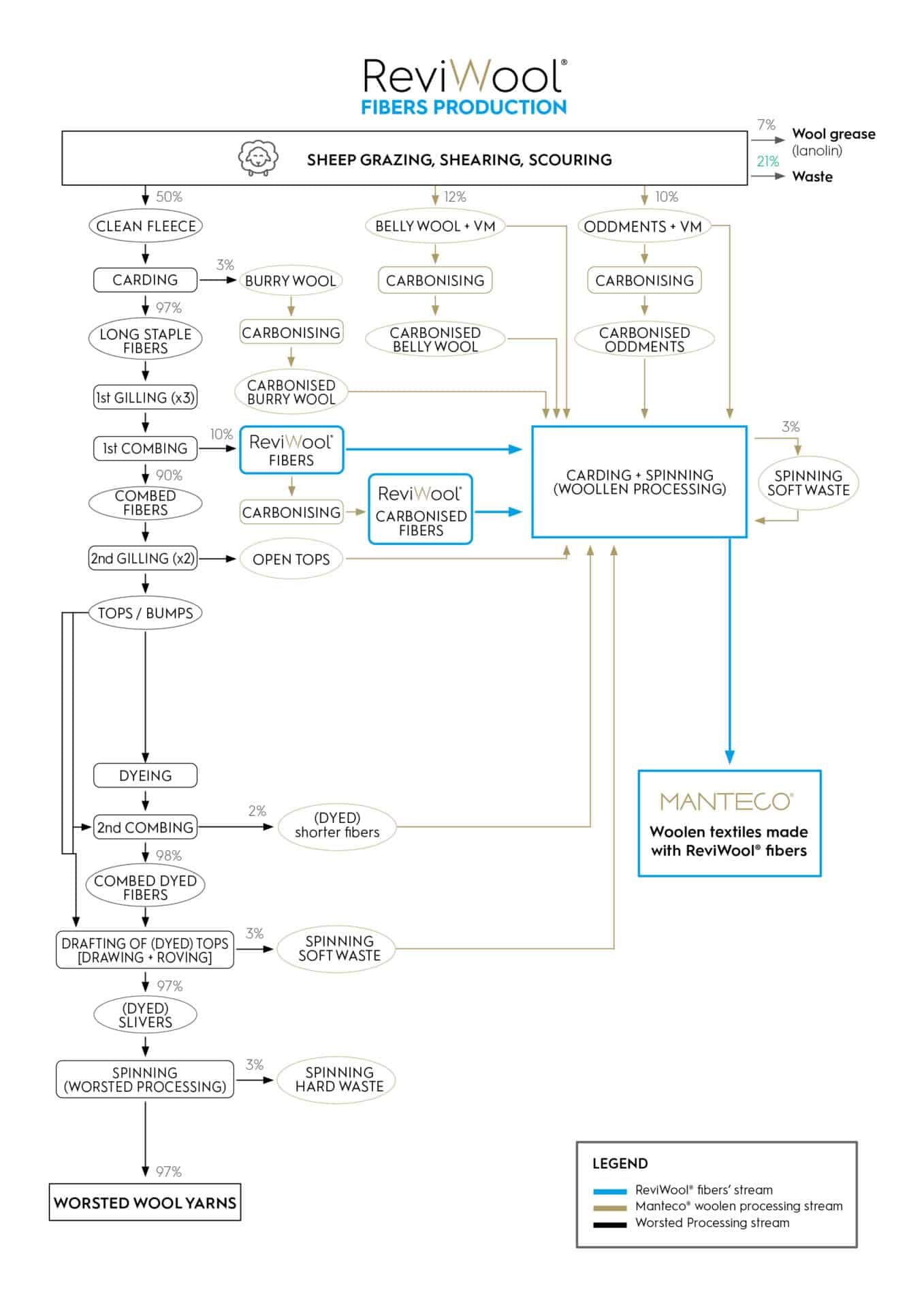

ReviWool® is made of valuable co-product fibers coming from the worsting process of virgin wool, which instead of being wasted, are recovered and masterfully processed through the woollen process to create premium quality textiles with a lower environmental impact, all guaranteed by our MSystem zero-mile and specialized supply chain.

The low-impacts of ReviWool® fibers were calculated through the world’s first LCA study that maps and assesses ALL wool materials’ impacts.

Discover the reasons why ReviWool® represents the new frontier for low-impact virgin wool fabrics

Nr. 1

It has all wool's natural amazing features

ReviWool® is a guarantee in terms of quality and durability, and it features all the natural characteristics of virgin wool: it is soft, breathable, elastic, wrinkle, odour and stain resistant; thermo regulating, fire and UV resistant.

Nr. 2

It promotes value capture and enhances wool production cycles’ efficiency

Through ReviWool®, Manteco is committed to provide zero-waste, premium quality virgin wool fabrics by optimizing the value chain and avoiding the wastage of precious co-product fibers: they are recovered and turned into premium textiles through the woollen processing. During the “combing” phase of virgin wool fibers, approximately 10% of fibers fall down, but instead of being wasted, they are recovered and manufactured by Manteco®.

Nr. 3

It has reduced impacts, compared to generic virgin wool tops, assessed by science-based studies

ReviWool®, compared to generic virgin wool tops, impacts 65,6% less on climate change, 65,5% less on water use and 65,6% less on total energy consumption. These impacts were calculated with a life cycle assessment, in accordance with the international standard UNI EN ISO 14040 series. ReviWool® fabrics' low impacts were calculated and certified according to the international EPD® scheme, in accordance with the international standard ISO 14025.

Nr. 4

It is manufactured in a specialized and local supply chain

ReviWool® fibers are turned into zero-waste, premium textiles within our MSystem supply chain, a unique network of 50+ expert textile businesses located within an area of 10 miles from our headquarter. Our supply chain is in the Prato textile district, in Tuscany, which has been processing wool for centuries and is therefore a guarantee of scalability, reliability and quality.

Nr. 5

It respects the Manteco Standard for Animal Welfare Guarantee

Manteco requires suppliers of animal fibers to sign and adopt a special animal welfare standard, which is based on industry best practices in accordance with the IWTO Guidelines.

Nr. 6

It can be (RWS) Responsible Wool Standard-certified

The Responsible Wool Standard (RWS) is a voluntary standard that addresses the welfare of sheep and the stewardship of the land they graze on, ensuring wool is produced responsibly, with respect for environmental integrity, and in line with the Five Freedoms of Animal Welfare: Freedom from hunger and thirst; Freedom from discomfort; Freedom from pain and disease; Freedom to express normal behaviour; and Freedom from fear and distress.

Nr. 7

It can be made with ZQ Merino Fibre

ZQ is a programme focused on responsibility and traceability in wool supply chains. ZQ certified wool has been produced in alignment with ZQ’s five values: animal welfare, environmental sustainability, traceable to source, social responsibility, and quality fibre. ZQ also ensures that the sheep producing the wool are not subjected to mulesing.

ReviWool® fibers' reduced impacts were analysed with a one-of-a-kind Life Cycle Assessment in collaboration with Politecnico di Torino

After in-depth studies and assessment of the entire wool supply chain, we managed to achieve a Life Cycle Assessment calculation for our ReviWool® fibers. Our study, in collaboration with the prestigious Politenico di Torino, firstly provides a detailed mapping of processes and products involved in the wool production chain, from the sheep grazing to the yarn production, with particular attention to the woollen part. Secondly, this study analyses the environmental impacts of the different intermediate products. It results that shorter fibers, used in the woollen processing, generally have lower impacts than longest fibers addressed to the production of fine yarns. This study was also peer-reviewed and published as a scientific article on the Journal of Cleaner Production.

Specifically, Manteco’s ReviWool® fibers, compared to generic virgin wool tops, impacts 65,6% less on climate change, 65,5% less on water use and 65,6% less on total energy consumption.

ReviWool® fabrics' impacts were also calculated and certified according to the international EPD® scheme

An EPD® is a certified Environmental Product Declaration, which trasparently reports environmental data over the life cycle of products in accordance with the international standard ISO 14025. ReviWool® fabrics’ EPD® is available here. Why is the EPD® so important? Because it is based on the international ISO standards, assuring international use, acceptability and continuity; it is based on scientific principles for Life Cycle Assessment (LCA) and approved through independent verification; it is based on specific rules for different product groups (PCR) ensuring that EPDs within the same category of products are calculated and presented in the same way; it provides a tool for communicating additional information such as social responsibility, quality control and environmental management.

The impacts of Noble fabrics, made with ReviWool® and cashmere, were also calculated and certified according to the international EPD® scheme

Sign up for Manteco updates

Type your e-mail address and stay up to date on Manteco news, events and initiatives