What is the difference between Worsted and Woolen textiles?

Discover all the differences to be kept in mind in order to better understand when and where one works better than the other

When you go shopping for your new - or even vintage - wool garment, you need to keep in mind that there are 2 different kinds of wool textiles: worsteds and woolens.

They’re both wool, aren’t they? Yes, indeed. And that is the major reason why all this can be very confusing and make people wonder if they are just two different words for the same thing. Well, both these materials are made of wool, but the starting fiber, their manufacturing processes, and their resulting products are quite different.

What is the watershed of these two different products?

As the International Wool Textile Organisation has it, “The wool fibre, depending on its length and fineness, can be turned into an amazing range of woven and knitted fabrics”. In fact, it all starts after the shearing of sheep, as wool has both long and short fibers. First, wool is washed hot water and detergent to remove general contaminants, such as dirt, salts from suint and non-wool protein material (the process is called “Scouring”), then fibers are dried and undergo a process called “carding”, which is a mechanical process that help to clean, disentangle, and mix the fibers.

The latter anticipates the process that makes our two different kinds of wool take two different ways: the “Combing”. During this phase, wool fibers are processed with a pinned cylinder that straightens long fibers and remove shorter fibers (approximately 10% of the entire quantity), which are not considered as waste, on the contrary. From this point on, long and uniform wool fibers will go through the worsting process, while shorter wool fibers (also called “noils” or “blouses”) go through the woolen processing.

Let’s start with WORSTED TEXTILES, how are they made?

So, after being divided from short fibers, long wool fibers are recombined to form a sliver, which is basically a strand of fibers. Then, the sliver is ‘gilled’ (to straighten the fibers by stretching the sliver) and turned into what is called ‘top’. The latter is made thinner by drawing it down into a finer sliver, called ‘roving’. The roving is then spun (twisted) to form a worsted wool yarn. After all these complex operations, the newly created worsted wool yarns can finally be woven into fabrics or even knitted to create sweaters (knitwear).

Pills of History about “Worsteds”

It is named after the small English village of Worstead, in the county of Norfolk, which, together with North Walsham and Aylsham, was a flourishing manufacturing center for yarns and cloths in the 12th century. At that time, new breeds of pasture sheep were introduced in England, such as the Teeswaters, Old Leicester Longwool and Romney Marsh. These animals were raised in enclosed pastures with plenty of nice tall grass and produced long-staple wool; at the expense of older breeds, which did better in rougher environments and produced short-staple fibers. At the same time, a huge migration of Flemish textile weavers, fullers and dyers was taking place in England, and many of them just settled and started working in Worstead, by also introducing new spinning and weaving techniques. The type of cloth they produced came to be known only as “worsted”. The worsted cloth was often referred to as “stuff”, with cloth generally reserved for woolens.

…But what about WOOLEN TEXTILES, how are they made?

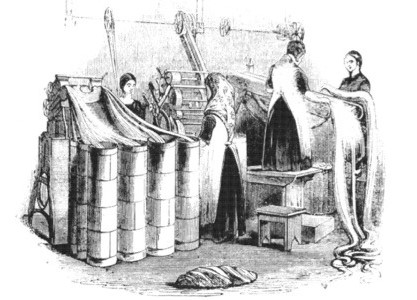

So, after being divided from long fibers during the combing phase, short wool fibers undergo the “carding” phase. The name carding comes from the Latin “Carduus” or teasel because carding was originally said to have been done with teasel heads. Here, a machine with wire-covered rollers disentangles and parallelizes the fibers to form a web, which is then split into narrow strips called “slubbings”. The latter are stretched and twisted to form a woolen wool yarn. Even here, after all these complex operations, the newly created woolen wool yarns can finally be woven into fabrics or even knitted to create sweaters (knitwear).

Neither is better than the other. However, there are some differences to be kept in mind in order to better understand when and where one works better than the other. Let’s see them all here below:

Nr. 1

THE FIBERS USED

Worsted textiles are always made with long-staple wool fibers, while woolen textiles are generally made with short-staple fibers (even though the woolen processing can be – and in some cases is – made also with long-staple fibers). This first, important difference influences all the rest, as – obviously - raw materials are the starting point of textiles.

Nr. 2

HANDFEEL AND LOOK

Due to the difference of fibers used and the different spinning processes, woolen yarns are bulky and uneven (with lots of short fibers and more pokey-out bits), while worsted yarns are fine and smooth. Therefore, worsted wool fabrics are finer and more even than woolens, which tend to be fluffier, thicker, and less even. This should not be considered as something that is set in stone, as depending on the spinning, weaving, and finishing, sometimes woolens’ handfeel and look can really resemble those of worsteds, or vice versa.

Nr. 3

FEATURES

Thanks to the shorter fibers they’re made of and the spinning process they undergo, woolen textiles are extremely insulating and softer; while worsted textiles are less insulating, but they hold creases and shape better. Some say that worsteds are more durable than woolen, but even here, it is not something set in stone. This is because the general durability features, such as pilling and abrasion resistance and tear strength, strongly depend also on the twisting-rate of yarns, the weaving (tighter or looser) and the finishing applied to the fabric, which could alter the fabric.

Nr. 4

END USES

Being heavier, thicker, and fluffier, woolen textiles are usually considered as ideal for warm winter coats, overshirts, jackets, sweaters, skirts, and blankets. On the other hand, worsted fabrics are most likely to be seen in formal suiting, and in trench coats and other fine outerwear garments.

Nr. 5

THE PRICE

Considering the initial quality difference of the wool fibers that are used, and the differences in the manufacturing process, worsteds will definitely be more expensive than woolens.

Nr. 6

…PLUS, THE WOOLEN PROCESS, UNLIKE THE WORSTED ONE, IS ALSO USED TO PRODUCE RECYCLED WOOL FABRICS

In conclusion, when it comes to choosing between a woolen and a worsted, there really is no right or wrong answer, IT JUST DEPENDS ON NUMEROUS FACTORS.

Now that you have learned everything you need to know about these two different textiles, you have the right knowledge to stay away from preconceptions and manage to make choices with a different – and more proper – awareness of what you are buying. However, the problem is that when you go shopping for your wool garments, most of the time, brands do not say if it is worsted or a woolen. Just go ahead and ask for it!

About Manteco, Italian premium textiles and circularity since 1943

After decades in the fashion world, in 2018, we have created the Manteco Academy project, through which we give webinars, in-person lessons and workshops on eco-design, circular economy and sustainability to numerous fashion schools, technical universities and brands worldwide. Thanks to this educative commitment and our heritage, we are often invited as guest speaker at events, panels, podcasts and conferences about sustainable fashion and circular economy.