What is machine-washable wool: ‘Superwash’ and more sustainable solutions

Discover more about the pursuit of easy-care, machine-washable wool garments

Wool boasts an impressive array of natural and favorable characteristics, but it is not machine-washable, and this is something that does not fit people’s busy life and the impracticality of handwashing every piece of clothing…

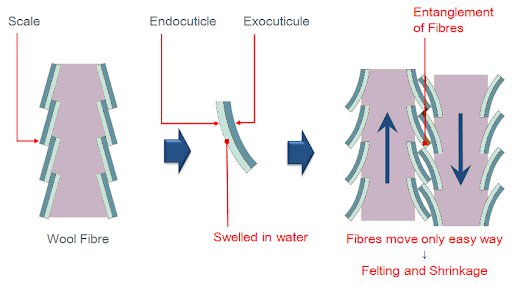

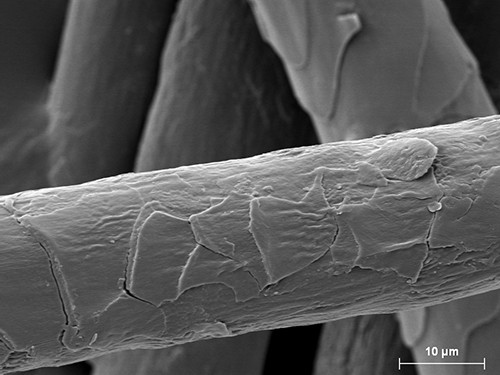

To comprehend this concept, let’s delve into the foundational aspects of wool fiber. Belonging to the keratin protein group, wool inherently possesses remarkable qualities such as natural elasticity, resilience, and absorbency. What distinguishes this fiber is its distinctive structure—its external layer features scales and is hydrophobic, repelling water, while the inner core is hydrophilic, readily absorbing moisture. In the natural realm, this unique composition empowers sheep to endure light rains, maintaining waterproofness, and enables them to withstand extreme temperature fluctuations.

The hydrophilic core of wool allows it to absorb approximately 30% of its weight in moisture without feeling damp, as the water is retained inside, and the hydrophobic outer layer imparts a water-repellent sensation to the touch. Furthermore, wool’s special structure facilitates efficient water transport. In scenarios like sweating, it effectively wicks moisture away from the skin, releasing it into the atmosphere (Read more on Why should you wear wool in Summer). Wool also showcases rapid drying capabilities and resistance to retaining odors.

But why are wool garments always handwashed then?

What happens if you machine-wash wool?

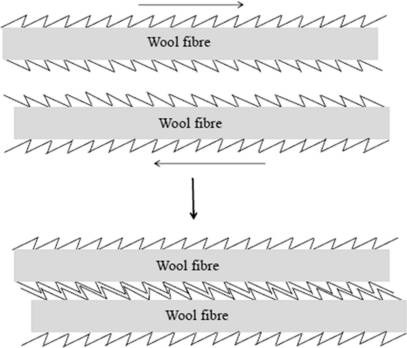

As the scaly wool fibers interact through friction, moisture, and abrupt temperature shifts, such as those encountered in a washing machine, the scales adhere to one another, akin to the mechanism of Velcro, leading to shrinking and felting. The more fibers rub, the closer they lock together, making a dense, fuzzy fabric, and once this happens, it is really difficult to un-felt it (Read more on Wool shrinkage, is it fixable?). This is why wool is always washed by hand. However, recognizing the demands of a busy life and the impracticality of handwashing every wool item, Superwash wool emerged in the 1970s…

What is ‘Superwash’?

Superwash treatment is used to prevent wool from felting in the washing machine. To render wool suitable for machine washing, you have to get rid of the wool’s scales. The Chlorine-Hercosett process, employed in approximately 75% of all superwash-treated wool, represents the most prevalent method. This method combines both techniques to ensure effective treatment. Initially, the fiber undergoes chlorination, involving exposure to chlorine gas or a chlorine solution. This step serves the dual purpose of eliminating the natural 18-MEA (18-methyl eicosanoic acid, a fatty acid that aids in water repellency) coating on the fiber and etching away the scales’ edges. In the subsequent step, a polyamide-epichlorohydrin resin, commonly referred to as Hercosett 125, is administered to the fiber (source).

The elimination of 18-MEA and the scaling edges facilitates the even distribution of the resin. When the resin is applied, it forms the ‘superwash’ coating, effectively preventing felting and shrinkage.

Let's discover some more sustainable alternative to make wool machine-washable...

Nr. 1

The LANAZYM Process by Dr.Petry

An eco-friendly enzymatic process with protease enzymes which offers an ecologically clean alternative to Chlorine-Hercosett Treatment'. The applied enzymes modify the scales of the wool resulting in fibers with a reduced tendency to felting, while also maintaining their natural properties.

Nr. 2

EXP by Schöller

EXP stands for 'EX-Pollution' and is a process developed by the Schoeller Spinning Group. Instead of chlorine, it uses natural salts as an oxidizing agent, and then adds small polymer patches on the surface of the yarn to make it machine-washable. A very special advantage of the EXP process is that it - contrary to the standard superwash process - doesn't release any AOX pollutants into the waste water, making it a lot less toxic.

Nr. 3

Naturetexx Plasma® by Südwolle

Naturetexx Plasma® is a plasma treatment that modifies the surface of the individual wool fibres altering the scales on the fibre surface that cause felting, just by using electricity and air as raw materials. It stands as a real alternative to industry-standard chlorine-based technology, as no chlorine is used and no absorbable organic halogen compounds (AOX) is produced.

Nr. 4

WoolUp by The Woolmark Company and Jeanologia

A new, more eco-friendly process to make wool garments machine washable. The WoolUp treatment is a relatively simple dry process that treats product in garment state using an ozone treatment that modifies the surface of the wool fibres. It removes the tips of the scales and smooths the fibres which allows them to slide against each other without interlocking, thereby preventing felting and shrinking.

About Manteco, Italian premium textiles and circularity since 1943

After decades in the fashion world, in 2018, we have created the Manteco Academy project, through which we give webinars, in-person lessons and workshops on eco-design, circular economy and sustainability to numerous fashion schools, technical universities and brands worldwide. Thanks to this educative commitment and our heritage, we are often invited as guest speaker at events, panels, podcasts and conferences about sustainable fashion and circular economy.