What defines garments' recyclability?

Discover all the elements that enable or hinder the recycling of garments in the fashion industry

The main problem for adopting the circular economy in fashion

The importance of recycling textiles is increasingly being recognized, since – unfortunately – according to an important study report, « Transitioning to a Circular Textile Economy in Australia », it has been seen that “100 billion garments are produced globally each year, with 33% going to landfill within the first year of purchase, and just 1% of total collected disposed garments are recycled. Most of the remainder is burned in landfills or downcycled into less valuable materials”, representing a huge loss of materials each year.

In this scenario, garment recycling could really make the difference, but what is it?

It is the process through which post- and pre-consumer garments are recovered and brought back to the fiber state, in order to be re-used for producing new materials. This can be achieved in a mechanical or chemical way, depending on the fibres involved. The necessary steps in this recycling process involve the donation, collection, sorting and processing.

It would be good news if this processes were easy and quick, but there are many obstacles that hinder it. What determines the recyclability of a garment? Let’s see it!

How does composition influence garments' recyclability?

Composition is a key issue and the biggest challenge for garments' recycling. Most of the textiles that we wear are complex combinations of different fibers, which are difficult to separate for effective recycling.

Why are garments made with blends? Because this way different properties of their component fibres are combined. Sometimes, this practice is used to improve the appearance, comfort, performance and care of garments, yet most of the time it is used to reduce costs, by mixing expensive fibers with cheaper ones.

Let’s see some examples:

‘Polycotton’, a blend of polyester and cotton used for many kinds of garments. Compared to pure cotton, it has a higher durability, crease resistance, and lower cost, but still maintains a cotton ‘feel’.

Elastane is blended with other fibers to add stretch capacity to a garment.

Acrylic is blended with wool fibres to lower costs.

More complex blends of three – or more – materials are increasingly used to lower landed costs.

GOLDEN RULE: the more homogeneous the composition is, the more recyclable the garment will be.

In fact, monofiber materials (es: 100% Wool) are easily recyclable and will maintain a higher quality than mixed fibers. The resulting ‘new’ fiber will be versatile, easy to re-use for yarns and fabrics, thus enabling a garment-to-garment recycling; while tri- or bi-fiber blends make garments’ recycling very hard and will give life to a ‘new’ fiber that is not versatile.

How do trimmings and components hinder garments' recyclability?

When garments are eligible to be recycled, they start facing a long and tough journey to be brought back to a new life, and one of the biggest challenge in it is the presence of trimmingss and components.

When garments are collected, they are manually divided by compositions and colors (this phase is called ‘sorting‘), then they must be cleaned from non-recyclable elements, which are usually small elements, but – as they say – the devil is in the details, even more in recycling. This phase has a big effect on the speed and efficiency of the process, and most of the time it causes also a loss in terms of textile material.

Let’s see some of them:

All the parts containing elastane are cut off the garment

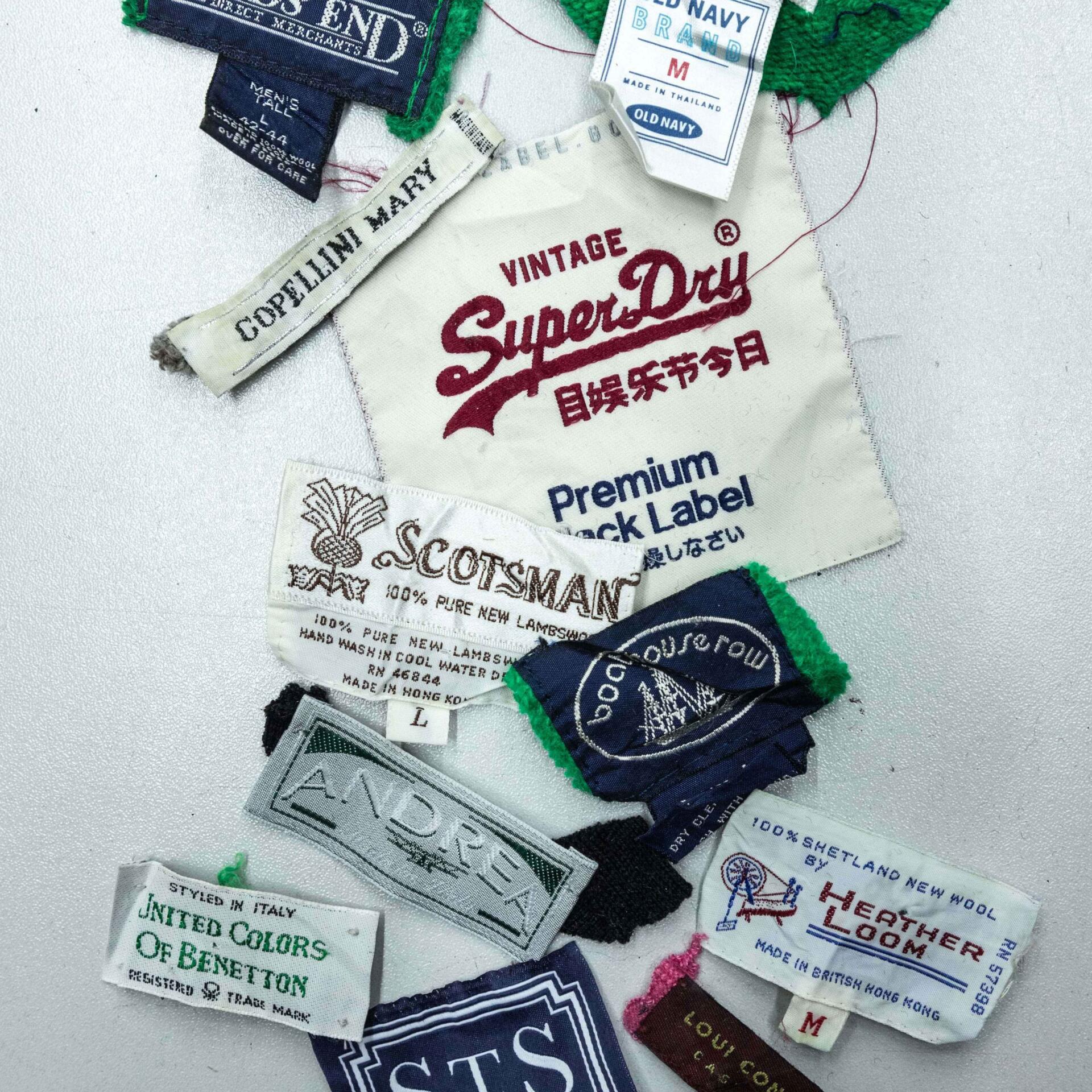

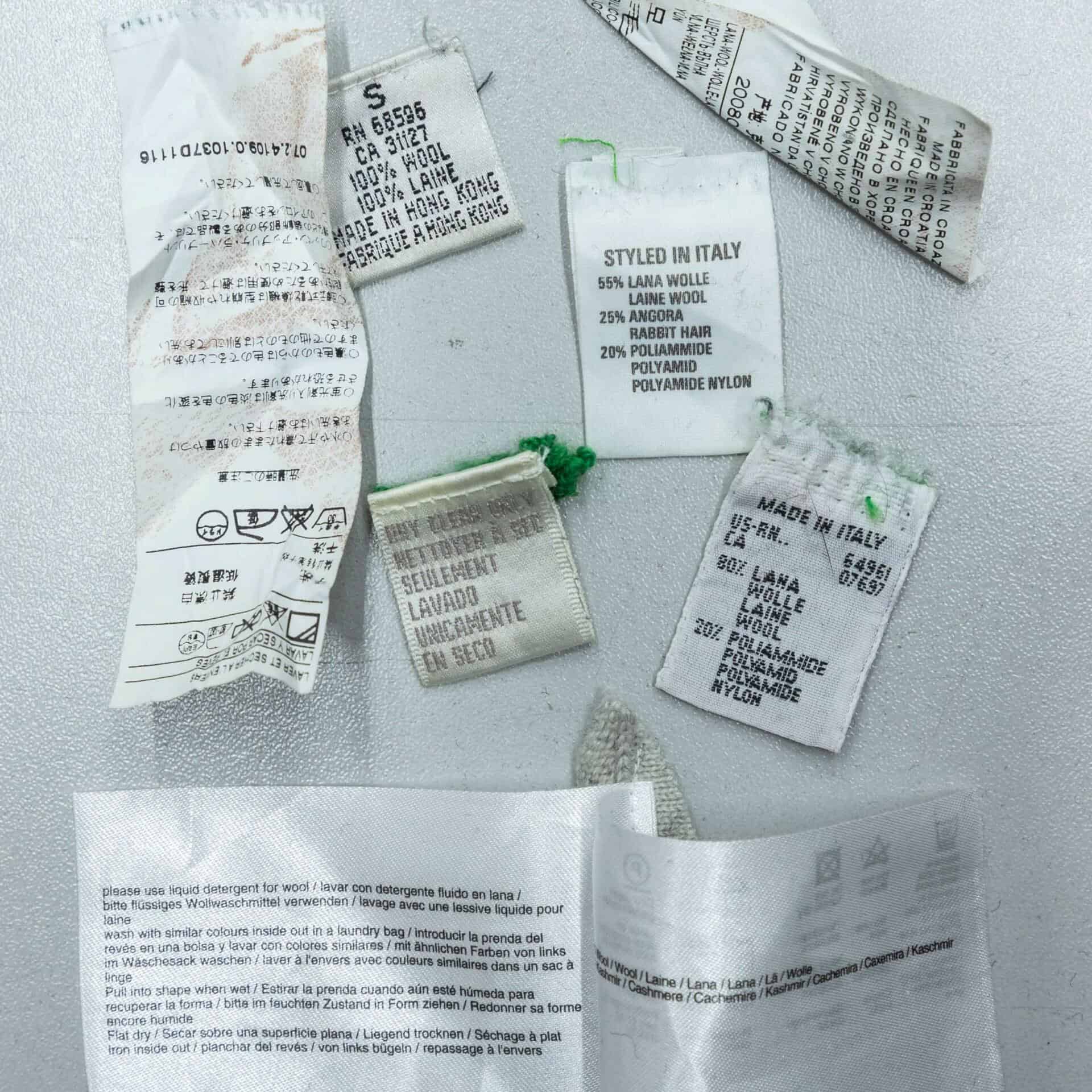

Brand labels and care labels are removed, as they are usually made of polyester and can subsequently hinder the recycling process and contaminate the composition of the ‘new’ fiber.

Zippers – and the part of fabric/knit they are stitched to – are cut

Buttons are manually pulled off the garment

Linings are taken out of the garment

Liners are cut off the garment, together with the part of fabric/knit they are bonded or stitched to

Embroideries are cut off the garment

And last but not the least, stitching made of a different material than the garments are cut off, together with part of the fabric/knit they stitched

GOLDEN RULE: The less components and trimmings the garment has, the more recyclable and less wasteful it will be.

The solution for winning this big challenge is designing for easy-disassembly: carefully considering how to design a product in a way that it is easy to disassemble after its life, using little or no trimmings, using fewer components, designing with fewer cuts, seams and embroideries.

Let's take a look at all the trimmings and components that are removed before the actual recycling process begins

How could designers increase garments' recyclability?

In the last few years, a new philosophy has risen in the world of fashion: Eco-design, also called ‘sustainable design’ or ‘circular design’. Why? Because 80% of a garment’s environmental impact is determined in the design phase, where the choice of raw materials, constructions and assembly deeply influence the recyclability, and consequently, circular economy in fashion.

Nowadays, Eco-design is still not very commonly used, but as the issues on environmental danger increases in awareness, more and more designers and brands are starting to adopt it, by taking into account garments’ lifetime impacts right from the start.

In order for garments to be recyclable, many factors must be taken into consideration when designing:

Using mono materials to ensure recyclability and enable an easier process

Avoid non-recyclable fibre blends

Designing garments for easy disassembly

Using sewing threads and labels of the same material of the garment

These are just some of the precautions to create more and more recyclable garments. We must design in a way that garments can have a prolonged life and close the open loop that has had billions of garments incinerated or landfilled.

About Manteco, Italian premium textiles and circularity since 1943

After decades in the fashion world, in 2018, we have created the Manteco Academy project, through which we give webinars, in-person lessons and workshops on eco-design, circular economy and sustainability to numerous fashion schools, technical universities and brands worldwide. Thanks to this educative commitment and our heritage, we are often invited as guest speaker at events, panels, podcasts and conferences about sustainable fashion and circular economy.